The VEVOR K11-125 5" Lathe Chuck is pretty versatile, especially when it comes to clamping different workpiece sizes. The manufacturer's product description notes that it has an internal jaw clamping range of 2.5-110 mm and an external jaw clamping range of 38-125 mm. This makes it adaptable for handling different materials, whether you’re turning metal or something more delicate.

According to our research, people tend to like how the jaws work and the overall quality. Just a heads up, though: it's recommended to take it apart and clean it when you first get it, since there might be some leftover debris from manufacturing. This is pretty common with tools in this price range, so it’s not out of the ordinary.

On the precision side, it's quite impressive, with a runout of about 0.003 inches. That accuracy is a big plus if you’re doing detailed work. It’s also self-centering, which definitely helps with precision and saves time by automatically centering the workpiece.

Just be sure to follow the setup instructions carefully to avoid any alignment hiccups. Some folks have mentioned they had issues at first, but they seem to be fixable with a bit of tweaking.

Overall, the VEVOR K11-125 5" Lathe Chuck is a solid pick for both hobbyists and pros in metalworking. You might need to spend a bit of time adjusting things at the start, but once you do, it should work like a charm.

Just remember to give it some initial love to get the best out of it right away.

Where to Buy

Considering the VEVOR K11-125 Lathe Chuck?

Here's our "TLDR" Review

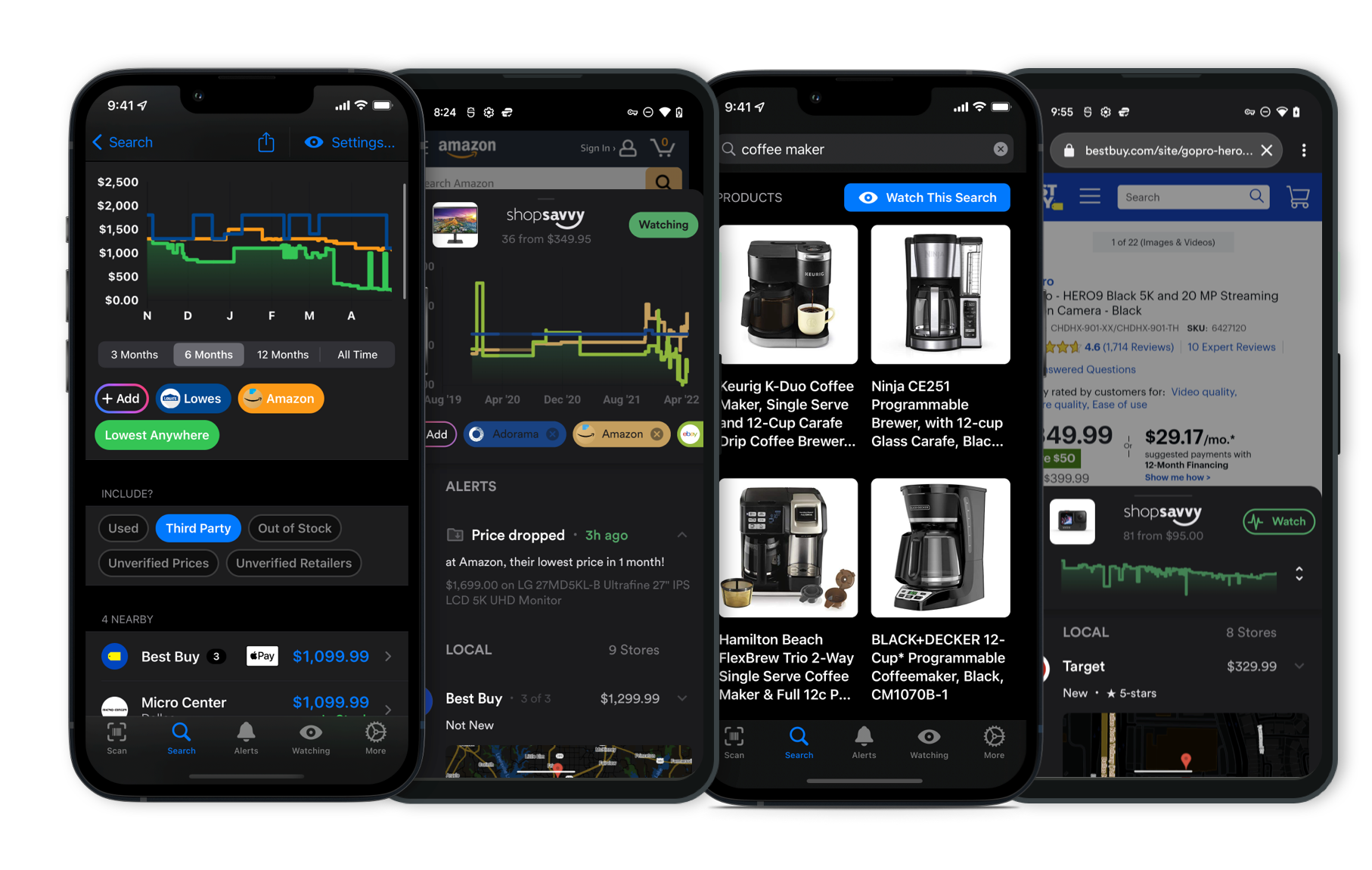

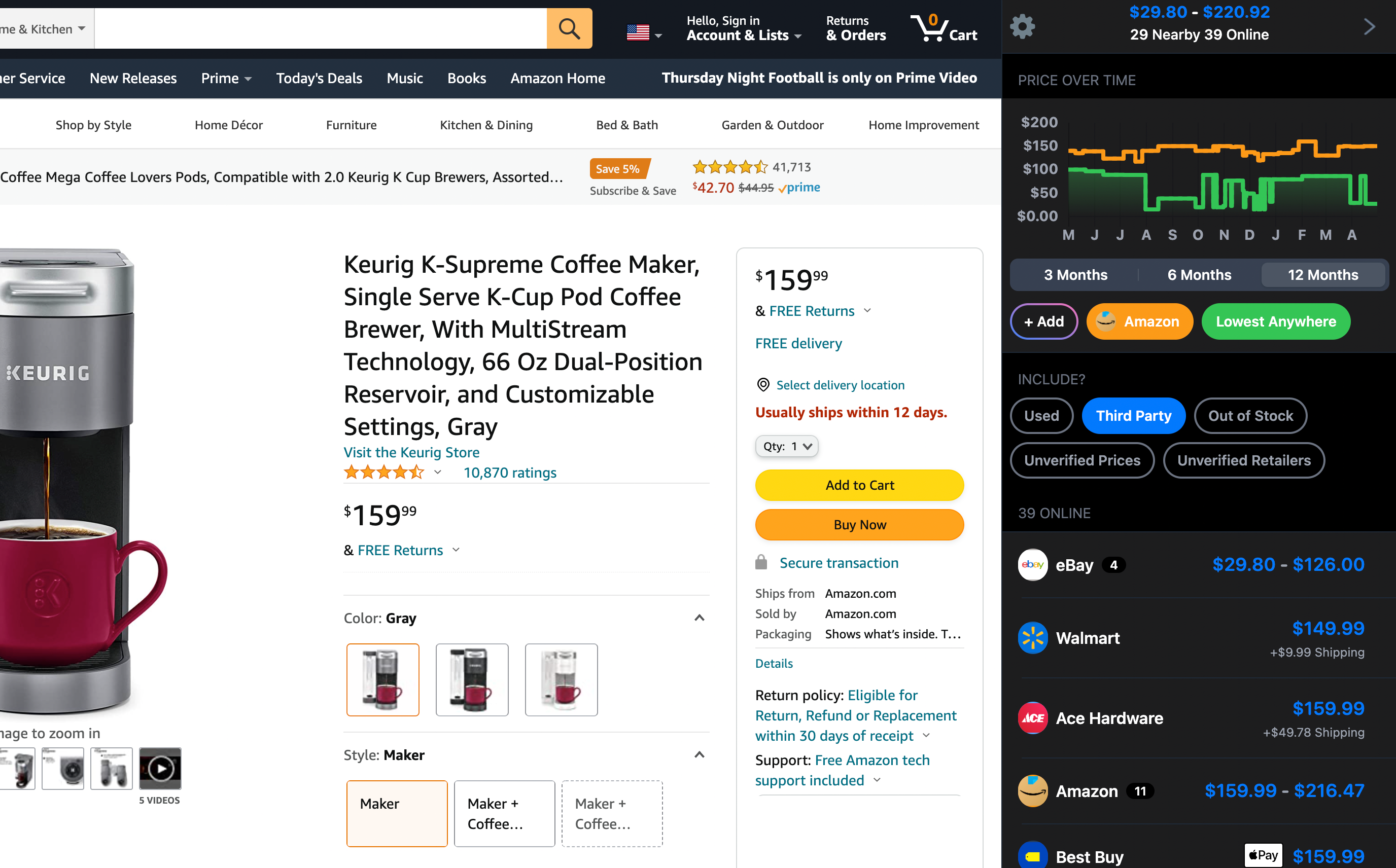

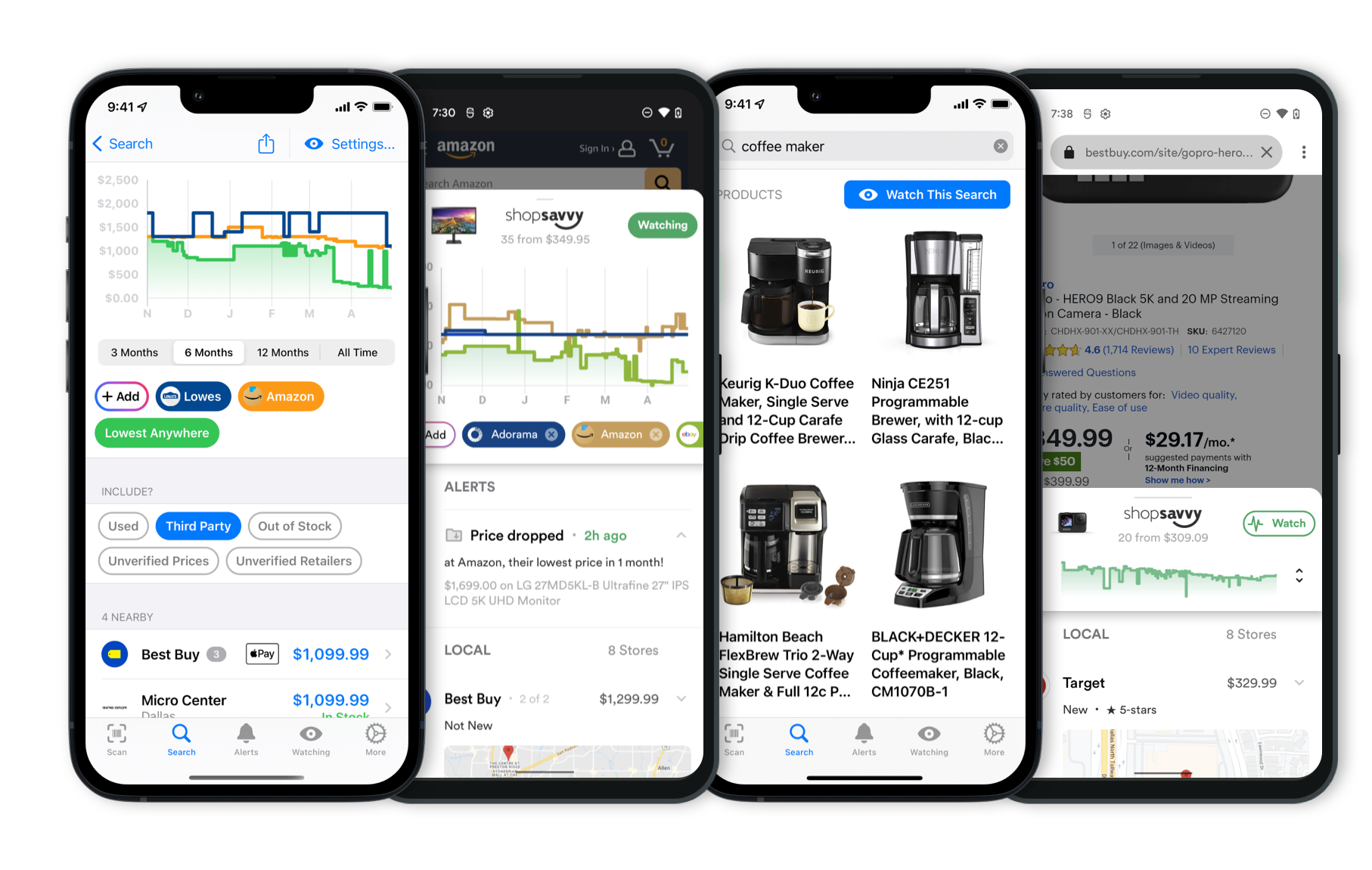

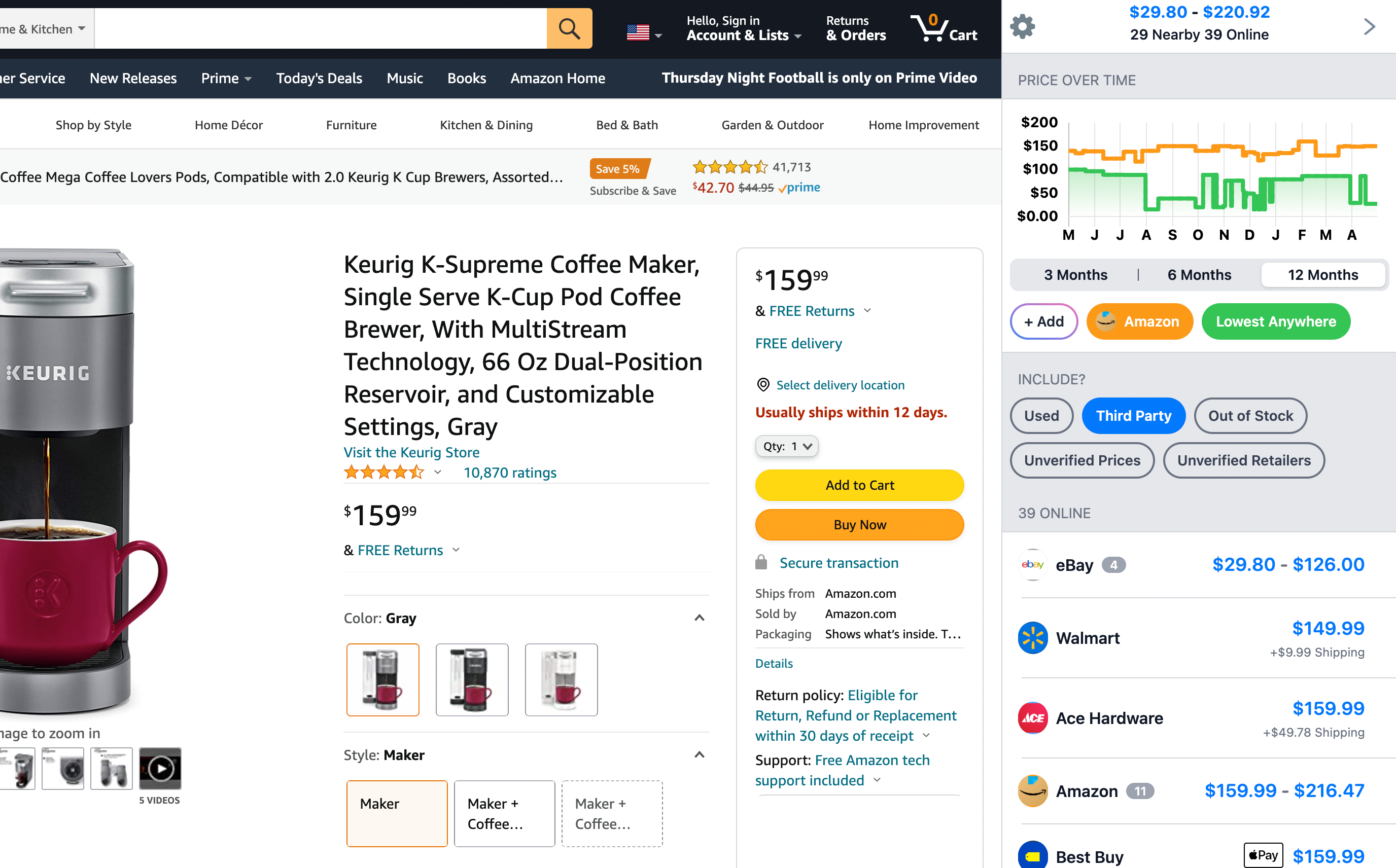

Download ShopSavvy App

Download ShopSavvy AppCompare prices for anything in real-time, set price alerts, watch for deals by keyword, and much more

Install ShopSavvy Browser Extension

Install ShopSavvy Browser ExtensionCompare and track prices automatically while you shop online at thousands of websites.

More Answers

If you're still curious about the VEVOR K11-125 Lathe Chuck, here are some other answers you might find interesting:

The VEVOR K11-125 Lathe Chuck is a handy tool for many machining projects, but a few things could come up that might need your attention. First off, you'll be working a lot with the T-key that comes with it. The manufacturer highlights this feature as essential for tweaking the chuck jaws, designed to make things easier on your hands.

That said, there are some quirks according to our research. A common issue involves the self-centering accuracy. Over time, especially if you use it a lot, you might find that it becomes less precise and could need some recalibration. The self-centering mechanism seems to wear out a bit, meaning the jaws might not always move perfectly symmetrically around the center after extended use.

Also, swapping out jaw types can be a bit of a hassle. Even though the chuck comes with both internal and external jaws for versatility, some people find the process of changing them a bit tricky. It's not always a quick task, so if you're in a rush, it might be frustrating.

Durability-wise, some think the chuck shows wear pretty quickly if you're putting it through heavy-duty tasks. This might come down to the materials used in its construction, which aren't necessarily geared for super intense machining without some wear and tear.

In short, while the VEVOR K11-125 Lathe Chuck has some great features like the T-key and versatility with the jaws, you might bump into accuracy and jaw-swapping issues.

Regular maintenance should help keep it in good shape, especially if you need precision. It's a pretty decent choice if you're looking for something budget-friendly to start with, particularly for beginners or more casual projects.

Taking good care of your VEVOR K11-125 Lathe Chuck is pretty important if you want it to perform well and last a long time. It’s got this nifty self-centering 3-jaw setup that’s great for precision work, so a bit of regular maintenance goes a long way.

To start, you’ll want to clean out any debris or old grease when you first get the chuck. Our research shows some people have found machining debris inside when it arrives, so clearing that out can make a big difference. You can use a solvent-based cleaner or a degreaser to get rid of the residue, but make sure everything’s completely dry afterward to avoid rust.

You'll also need to keep it well-lubricated. The manufacturer recommends using some suitable oil on the gear teeth and moving parts. Pay special attention to the jaws and gear mechanism, making sure they’re nicely oiled up after cleaning. Doing this regularly helps things run smoothly.

Every so often, it’s a good idea to take the chuck apart for a thorough cleaning and to check it out for wear and tear. When you take the jaws off, you can clean each piece separately and look for any damage, especially on parts like the scroll plate and jaws.

When you’re putting it back together, make sure all the parts are lined up correctly. Our data suggests that having everything snug keeps the chuck in top shape. You might want to test it with a piece to make sure the jaws are centered right and holding tight.

Also, keep in mind that you might need a specific mounting setup, like a three-bolt plate. It’s worth checking if your setup matches these requirements or if you’ll need to get some additional hardware.

Lastly, regularly check for wear on critical parts. If you notice any issues with the centering mechanism or the jaws getting loose, tackle those early. This way, you can avoid bigger problems down the road and keep your chuck working well.

By staying on top of these maintenance tasks, your VEVOR K11-125 Lathe Chuck should serve you pretty well for all sorts of machining projects. Just make these practices part of your routine, and you’ll be good to go.

The VEVOR K11-125 5" Lathe Chuck is pretty versatile, especially when it comes to clamping different workpiece sizes. The manufacturer's product description notes that it has an internal jaw clamping range of 2.5-110 mm and an external jaw clamping range of 38-125 mm. This makes it adaptable for handling different materials, whether you’re turning metal or something more delicate.

According to our research, people tend to like how the jaws work and the overall quality. Just a heads up, though: it's recommended to take it apart and clean it when you first get it, since there might be some leftover debris from manufacturing. This is pretty common with tools in this price range, so it’s not out of the ordinary.

On the precision side, it's quite impressive, with a runout of about 0.003 inches. That accuracy is a big plus if you’re doing detailed work. It’s also self-centering, which definitely helps with precision and saves time by automatically centering the workpiece.

Just be sure to follow the setup instructions carefully to avoid any alignment hiccups. Some folks have mentioned they had issues at first, but they seem to be fixable with a bit of tweaking.

Overall, the VEVOR K11-125 5" Lathe Chuck is a solid pick for both hobbyists and pros in metalworking. You might need to spend a bit of time adjusting things at the start, but once you do, it should work like a charm.

Just remember to give it some initial love to get the best out of it right away.

Explore Content

Footer 1

Published

Subscribe for Updates

Get the latest news, and updates on ShopSavvy. You'll be glad you did!